Leader in compact and innovative ovens for the e-mobility* industry

Leader in compact and innovative ovens for the e-mobility* industry

Leader in compact and innovative ovens for the e-mobility* industry

*electric mobility

ELMETHERM is the leader supplier of compact and innovative solutions for thermal processes and in the design and engineering of industrial ovens for the e-mobility.

Our industrial ovens are customized solutions in order to adapt to the new and special requirements of innovative and changing production processes, materials and products.

Our solutions

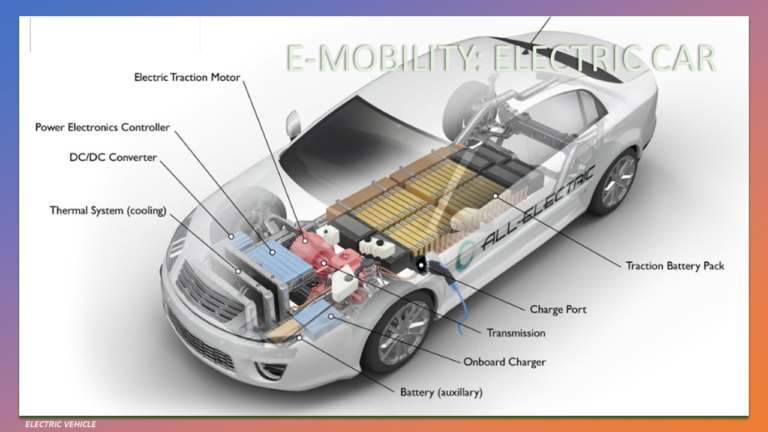

ELMETHERM provides a significant contribution to the development and implementation of innovative industrial projects in the automotive industry as actually for the electric mobility, e-mobility.

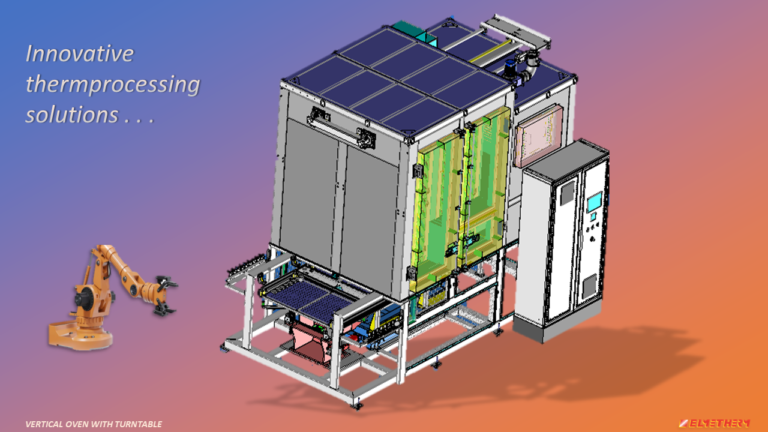

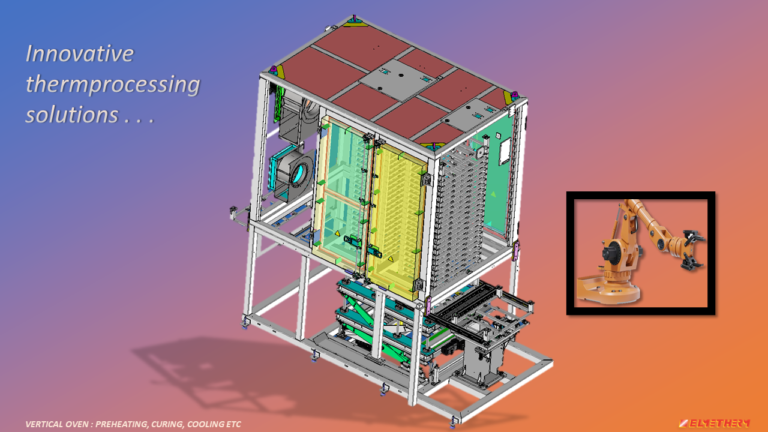

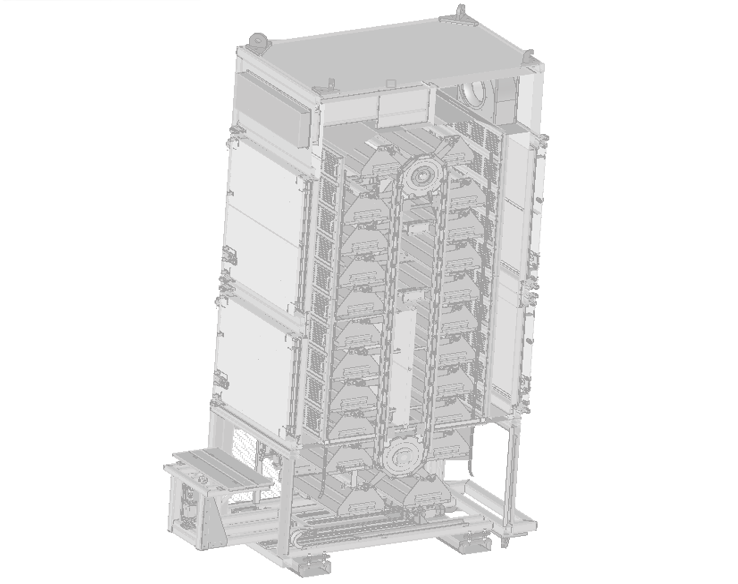

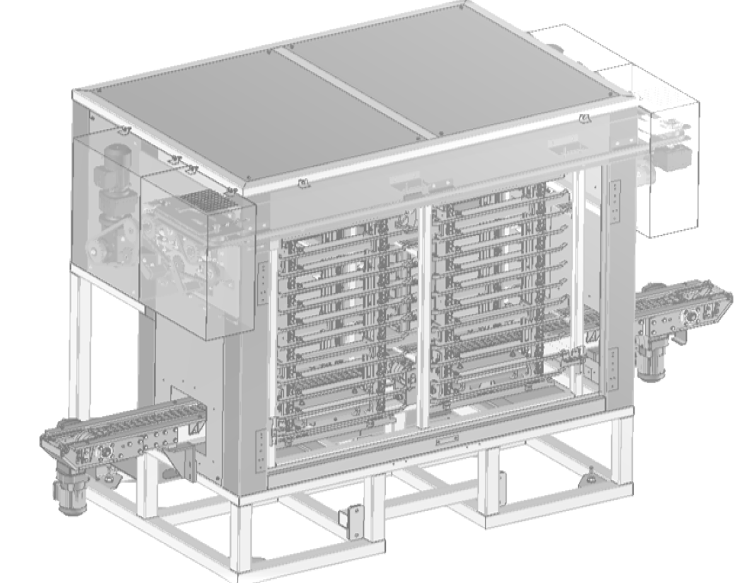

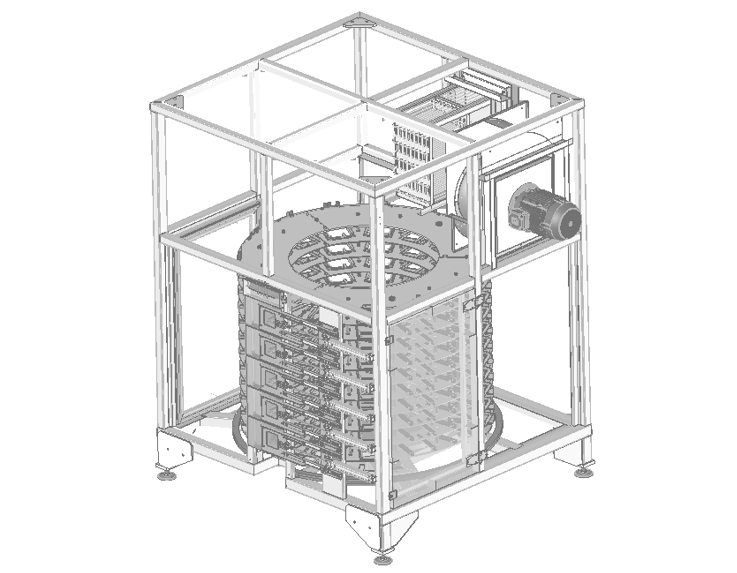

The vertical oven is a compact, customized thermal solution:

- Efficient, considering thermal quality (isotherm) and productivity (output);

- Cost saving by performing savings on precious plant space, consumed energy and limited maintenance;

- Easy and quick to build up and to relocate;

- Integrable into existing or forthcoming production lines;

- Automated, in combination with robots that perform repetitive and precise operations;

- Economical and competitive, linked to the degree of innovation, the price and maintenance requirements compared to standard ovens;

- Clean and environmentally friendly, due to a design that eliminates all mechanisms and substances that may cause contamination;

- Safe and compliant with current human-machine safety and environmental standards and laws;

- Multipurpose.

- EXCELLENT ISOTHERM

- PROVEN MECANICS

- LOW MAINTENANCE

Our processes

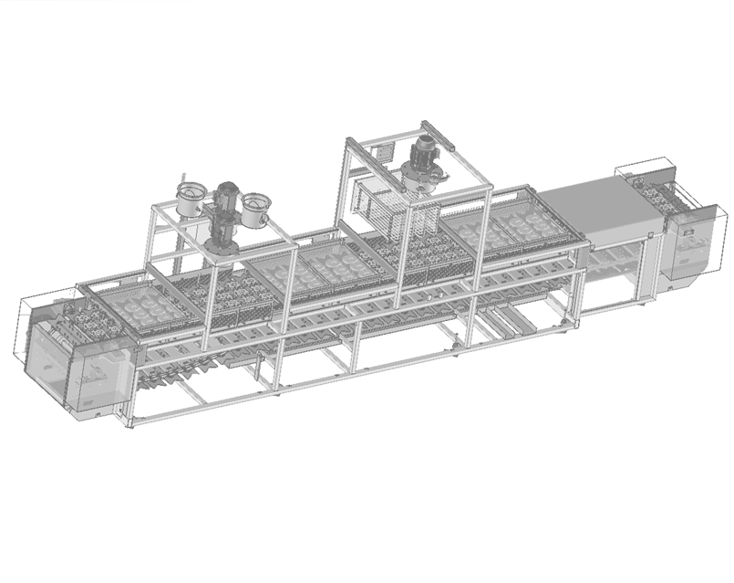

ELMETHERM compact ovens are flexible or multi-purpose, which means that they can be used for a variety of processes such as:

- Preheating

- Curing

- Polymerization

- Cooling

- Dispensing

- Potting

- Bonding

- Sealing

- Encapsulation

- Etc

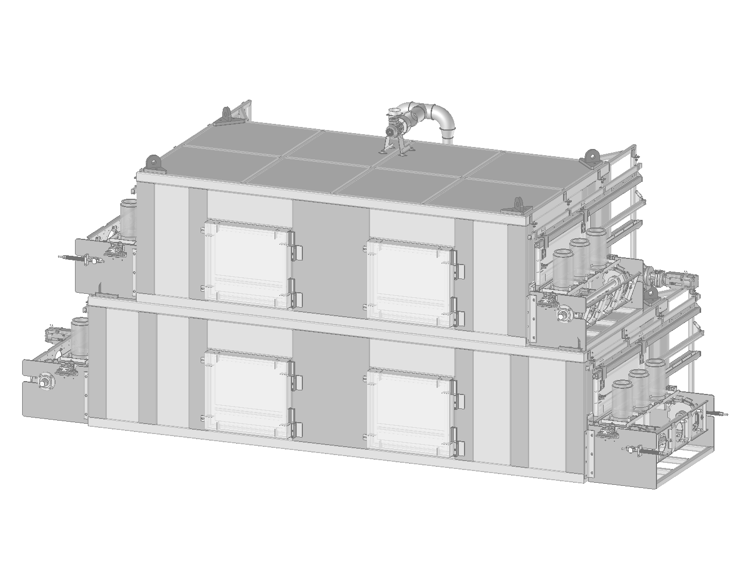

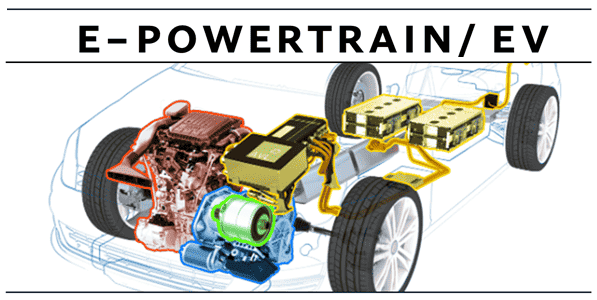

e-powertrain

Some examples of the application of ovens:

ELMETHERM ovens are used to transform materials and raw materials into innovative products which are essential to the success of projects in the automotive industry and the e-mobility in particular.

Some examples:

DC/DC converter

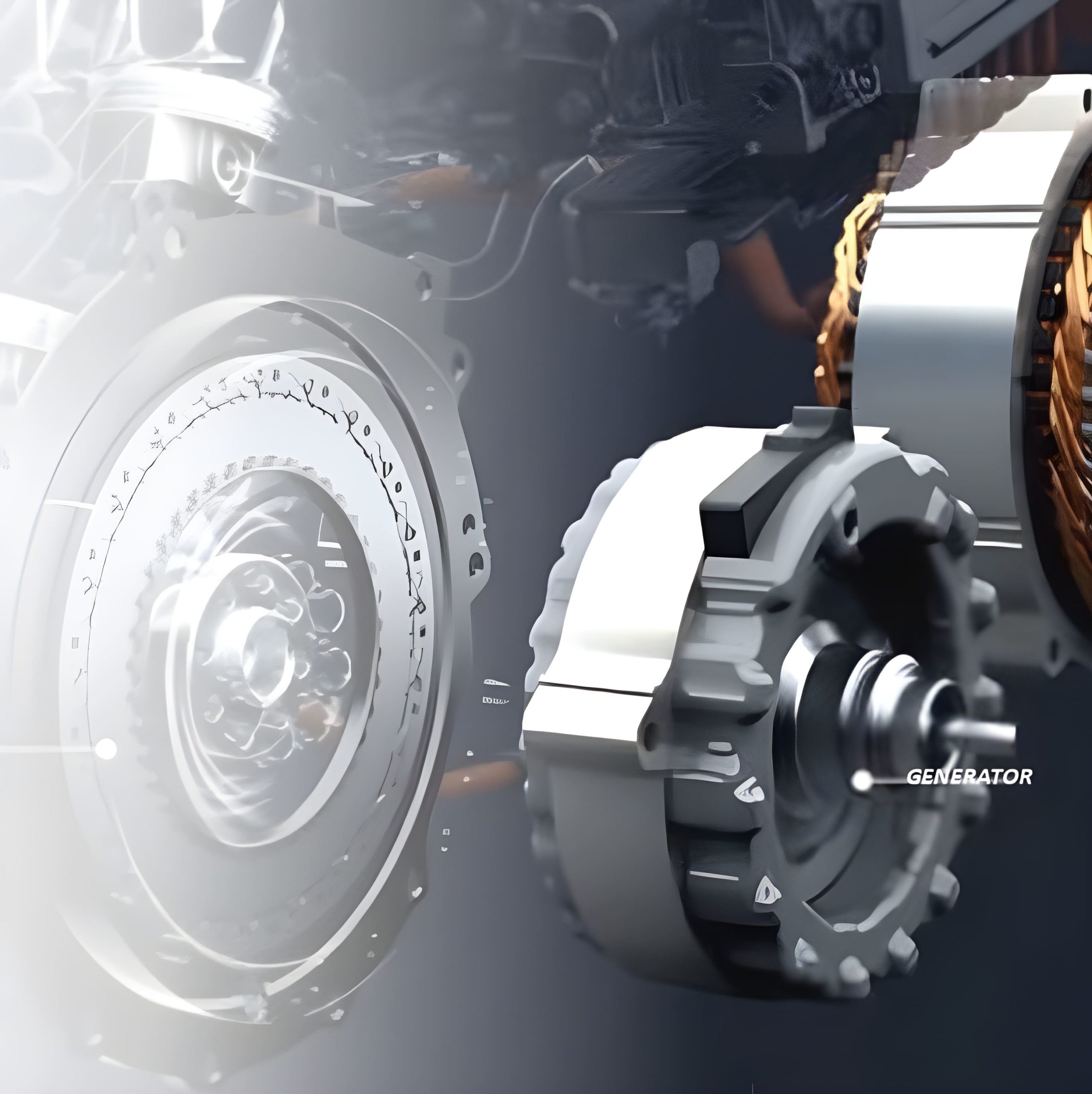

Starter alternators

Thermal management system

Battery thermal management (BMS)

Electric generator

Engine management systems

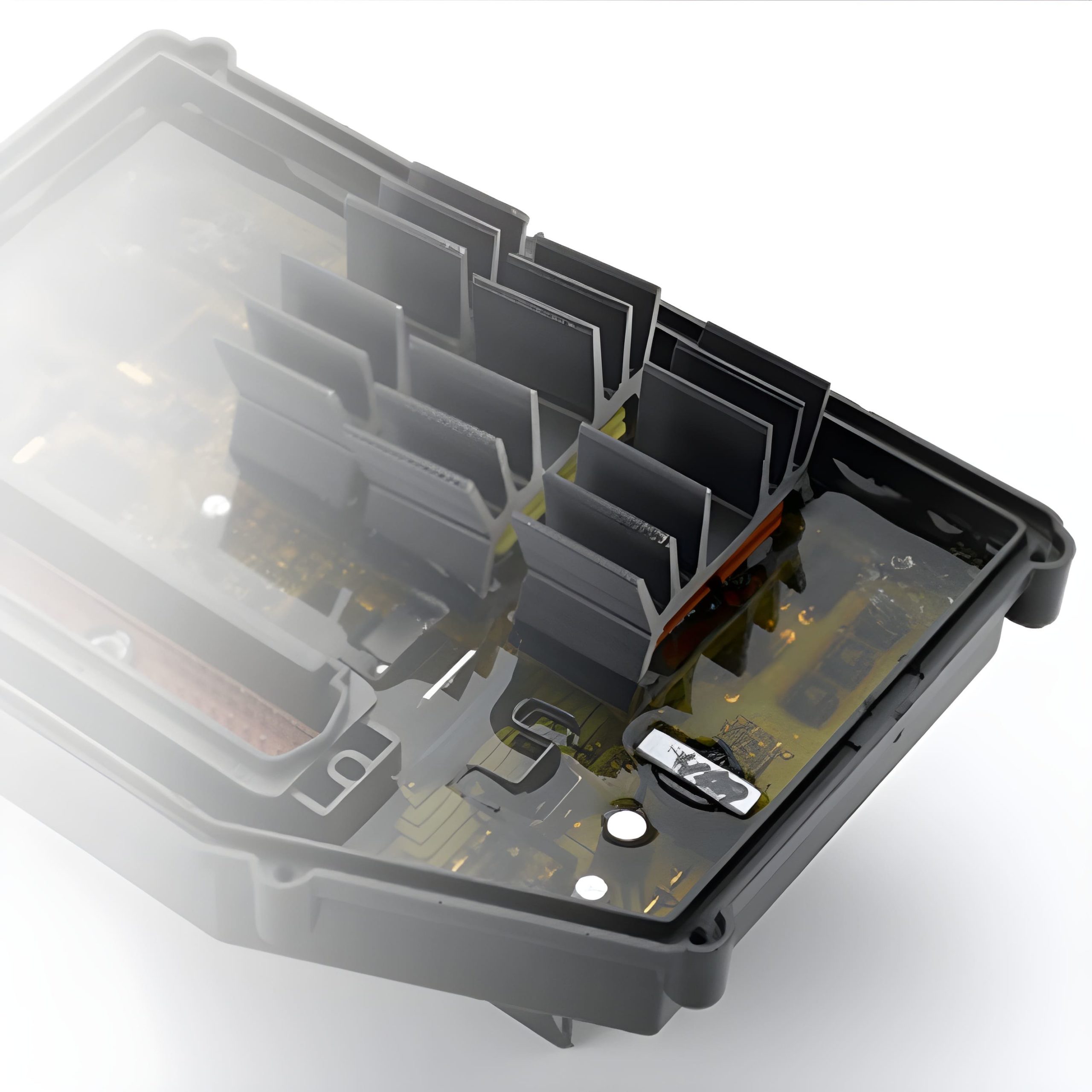

ECU / EMS

- Engine control or management systems

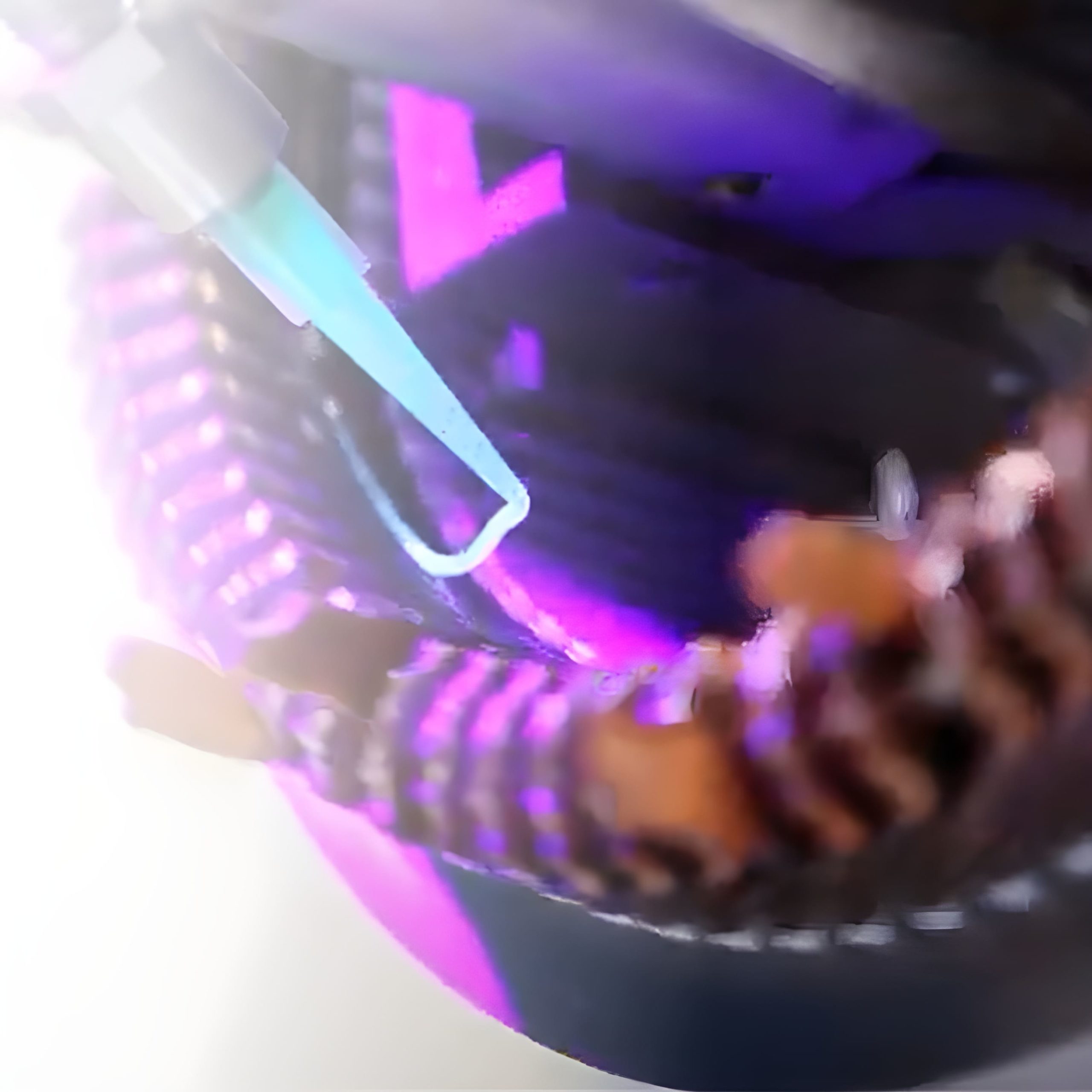

Impregnation of stators

Resin by run-off or immersion

- Resin Trickling

- Resin Dipping on stators

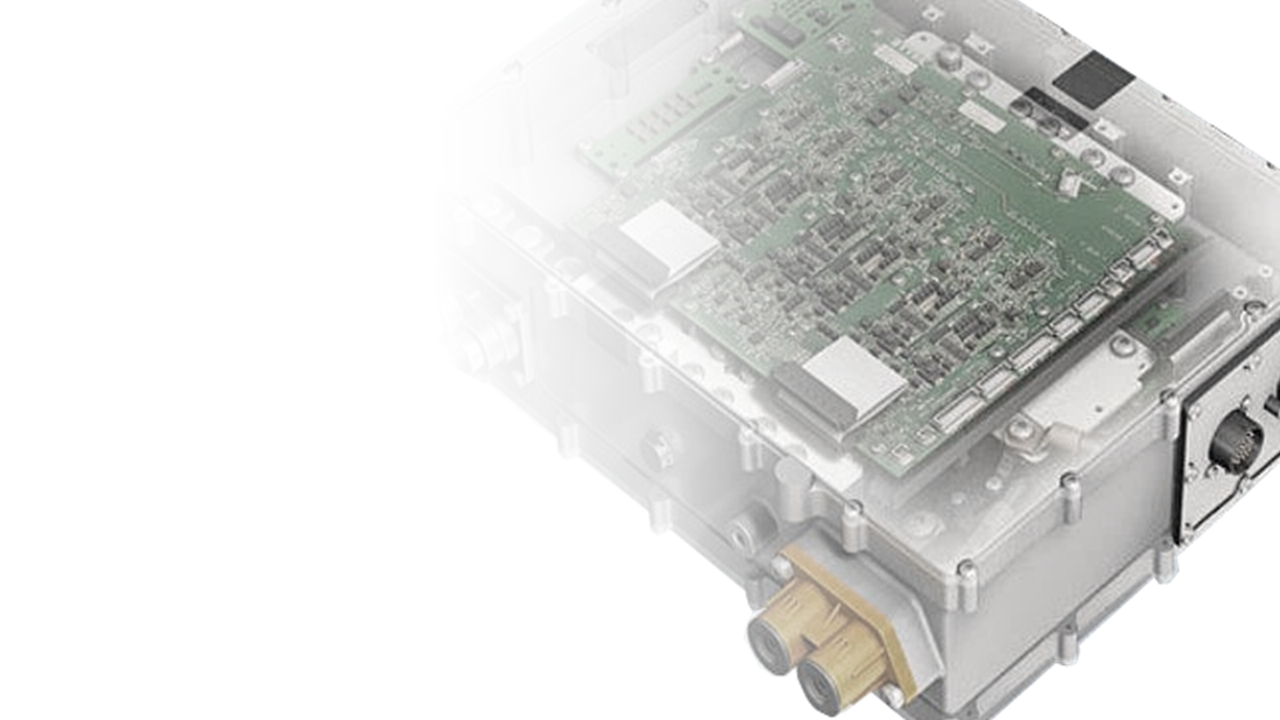

Power electronics

- Power electronic modules (PEM)

INVERTER